V-groove milling cutters on Alucobond®.

Nome Serie:

915.01/02

Click to enlarge images

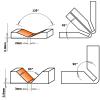

ALUCOBOND® plus composite panels can be formed using an extremely simple technique. The edge milling process makes it possible to manufacture three-dimensional elements of various types and formats. V-grooves are produced on the back of ALUCOBOND® plus composite panels. It is advisable to preserve some material at the base of the groove, for example on the inside of the cover sheet. The reduced thickness of the residual material therefore allows manual chamfering". No bending machines are required. The shape of the groove determines the bending radius. Grooves can be made with CNC machining centers, panel milling machines or manual vertical milling machines. The edge milling technique is suitable for ALUCOBOND® plus composite panels with all standard finishes.

The advantages of the edge milling technique are:

-minimal investment;

-Extremely simple processing technique;

-Bending does not necessarily have to take place in the workshop, but can be done on site, thus keeping transport costs low;

-economical production of facade components, frames, roof and attic edge coverings, closures, angles, etc.;

-Various structuring possibilities;

-high economic efficiency;

-bends are no longer limited by machine dimensions.

Complimentary "Formula 2050" vial with every order.

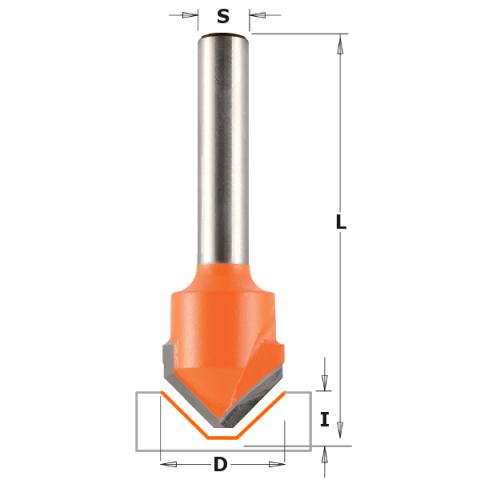

| Product | Product | Price | Buy | D | I | A | L | S | Favorites |

|---|---|---|---|---|---|---|---|---|---|

| 715.001.11 | 715.001.11 | 35,00 € | 18 | 7,4 | 90° | 60 | 6 | ||

| 715.002.11 | 715.002.11 | 37,60 € | 18 | 3,3 | 135° | 60 | 6 | ||

| 915.001.11 | 915.001.11 | 35,00 € | 18 | 7,4 | 90° | 60 | 8 | ||

| 915.002.11 | 915.002.11 | 37,60 € | 18 | 3,3 | 135° | 60 | 8 |

*All the prices include 22% Italian VAT

Follow us